How To Make Aircrete

HACKING AIRCRETE

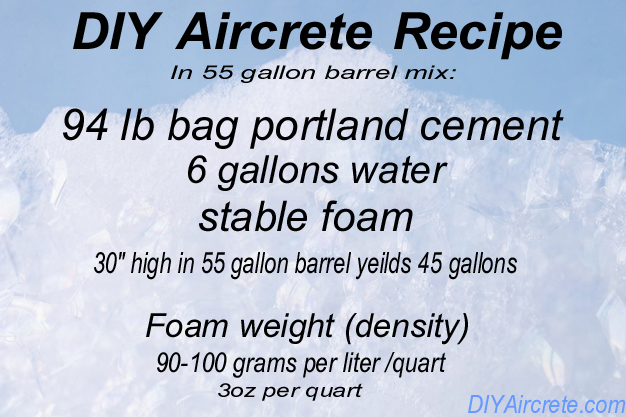

The basic recipe for aircrete consists of cement, water and foam.

The cement and water slurry are combined with a pre-formed foam (surfactant). This distributes a multitude of discrete air cells uniformly throughout the mixture. As the concrete hardens, the bubbles disintegrate leaving air voids of similar sizes to create a lightweight concrete.

Aircrete is very versatile and can be modified and adjusted for project size and need. There are many different mix design recipes depending on the application. The process for making aircrete yourself requires only basic skills and basic tools.

Below will be the open source recipe for making lightweight bricks or blocks suitable for a dome structure.

TOOL OVERVIEW :

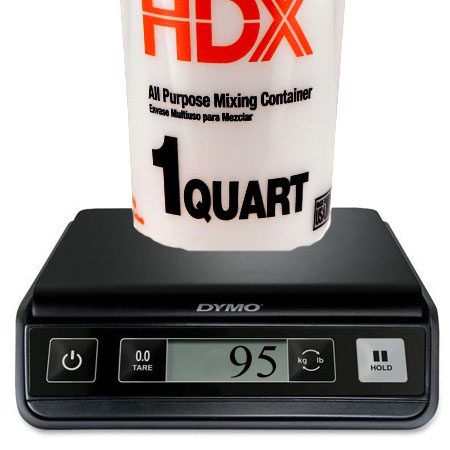

1. Small digital or postal scale :

The proper weight of the foam is crucial to achieving stable foam.

Place a 1 quart container onto the scale and tare/zero it out. Set it to measure grams. Fill the 1 quart container to top with foam and level the top by scrap off any excess. Place it on scale. The weight of the foam should weight between 90-100 grams or approximately 3 ounces per quart. If the foam is heavier then increase the air pressure or if the foam is lighter decrease air pressure.

Another, less precise, methods for testing the stability of the foam is to visually inspect the resulting foam. The foam should be the consistency of thick shaving cream. When applying a large dollop of foam to the palm of the hand and turning the palm downward the foam should cling and remain on the hand. Fill a large bucket with the foam and allow it to sit for several hours. If the foam stays firm with little or no collapsing, this is a good indicator that the foam is stable enough to stay firm for the duration required for the concrete to cure.

2. Concrete Mixer

at least 8 amp drill . It’s recommended to use a heavy duty commercial grade drill for mixing of cement. These are designed for regular repeated use.

A good quality concrete mixer is needed to mix your cement and water as well as incorporate your foam into your slurry. A cement mixing paddle can be attached to a drill to accomplish both tasks.

For small projects, some have had success creating suitable stable foam by adding a metal screen to their cement mixing paddle and mixing the proportioned soap and water solution together in a small bucket. This is a low cost technique for those testing or experimenting with aircrete who don’t want to incur the added expense of purchasing a foam generator or air compressor. However, if tackling large or varied aircrete project it’s highly recommend to purchase or make a foam generator.

Metal screen added to mixing paddle to increase foam thickness.

3. Foam Generator

A foam generator is a device that combines compressed air with a liquid foaming agent to produce a foam. These can be homemade or they can be purchased. (see link “Building The Best Foam Generator” or “Buying The Best Aircrete Foam Generator“)

4. Air Compressor

Minimum 90PSI rated for at least 2.5 cfm CFM: Cubic feet per minute is the volume of air being delivered by the compressor

MATERIALS OVERVIEW:

(1) Portland cement Any type

(2) Water

(3) Foaming Agent/Soap

popular aircrete foaming agents include:

Drexel, a commercial agricultural foaming agent (dilute 160/1 – 4 oz per 5 gallons of water) Drexel is one of the more effective foaming agents but does come with a warning label regarding skin irritation. Exercise caution when using product or foam around pets or children. Dawn or Seventh Generation Natural Dish detergent. (Dilute 40 parts water to 1 part detergent or 5 gallons water / 2 cups detergent) Suave clarifying shampoo: (30oz or 4 cups per 5 gallons) * Note 2 tablespoons of Vegetable glycerin can be added to increase foam and density of shampoo or dish soap used.

(4) 5 gallon bucket, 55 gallon barrel

(5) Wood forms, Molds or Containers: suitable to cure finished product.

(6) Safety glasses, gloves and dust mask Generally, cement dust particles are in the 10-micron range, which are captured by the inexpensive masks. wet cement can damage the skin. It’s abrasive and can cause redness, swelling and itching. Wear proper clothing, shoes and gloves. Be aware of wet and curing concrete as well as tools, buckets and run off around pets.

STEP BY STEP PROCEDURE

The quality and density of the foam need to be precise to achieve stable foam. If you do not use a good quality foam or it’s not the proper density your slurry will collapse during curing or result in a brittle end result.

(1) fill a 5 gallon bucket with water and add 2 cups dawn detergent (diluted 40/1 with water) or your preferred foaming agent.

(2) create foam with your compressor and foam generator

(3) Collect foam in quart container and weigh it on scale. Adjust your air pressure until you achieve the foam density between 90-100 grams. More air pressure reduces the weight of your foam. Less air pressure will increase the weight/density of your foam.

4) In a 55 gallon barrel, add 6 gallons of water and mix in a 94 lb bag of cement.

(5) Thoroughly incorporate foam into the 55 gallon barrel containing your cement slurry until you reach 45 gallons full.

(30″ inches high)

(6) Pour into forms or molds and allow to harden over night.

It takes approx. 30 days for concrete to cure but aircrete can typically be de-molded, cut and assembled after 24 hrs.

Image credit: "lightweightfoamconcrete" on Facebook